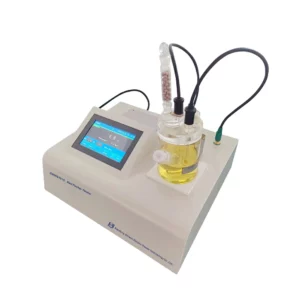

Products

ZWKL Oil Particle Counter

- Full-function 7-inch color touch screen operation, folding button design.

- High-precision laser sensor, wide test range, stable performance, low noise, high resolution

- According to customer needs, up to 64 detection channels can be set at the same time

- A variety of sampling containers such as standard sampling bottles or sampling cups can be used to meet the testing requirements of different industries

- Support custom standard test

Company Profile

The company specializes in the research anddevelopment, production, sales, and service of electric power systemautomation testing equipment, providing customers with one-stopservices.

Product Introduction

The instrument is designed on the principle of light resistance (shading method) and is used to detect the size and number of particles in the liquid. Can be widely used in aerospace, aviation, electric power, petroleum, chemical industry, traffic, port, metallurgy, machinery, automobile manufacturing and other fields in the hydraulic oil,lubricating oil, transformer oil, insulating oil, turbine oil, gear oil, engine oil, aviation kerosene, water-based hydraulic fluid solid particle pollution tests such as oil, And the detection of insoluble particles in organic liquid and polymer

solution.

Functional Characteristics

1.Adopt the light resistance (shading) method counting principle formulated by the International Hydraulic Standards Committee

2.High-precision laser sensor, wide test range, stable performance, low noise, high resolution

3.Using high-pressure syringe pump sampling method, the sampling volume can be set by yourself, the sampling speed is stable, and the sampling accuracy is high

4.Sampling system combined with positive and negative pressure can realize sample degassing, suitable for inspection of products with different viscosities

5.Built-in pressure sensor, you can directly set the pressure value, and automatically judge the air pressure in the cabin to ensure safety

6.The host has a built-in air purification system to ensure that the test is not polluted, and the degree of integration is high to avoid secondary pollution caused by the airtight connection between the air pump and the test system

7.Built-in multiple calibration curves, compatible with all commonly used domestic and foreign standards for calibration

8.Built-in GJB-420A, GJB-420B, NAS1638, GB/T14039, ISO4406, SAE4059cpc, SAE4059F, SAE749D, ГOCT17216, QC/T29104, JB/T9737, DLT432, HH005-2018 and more than ten commonly used standards

9.Support self-defined standard test, which can name the self-defined standard and make grade judgment

10.According to customer needs, up to 64 detection channels can be set at the same time

11.Built-in data analysis system, one test can give all standard test data and pollution level

12.Can carry out cleaning detection, pre-set the particle concentration required by the target cleaning, display the cleaning status in real time during the cleaning process, and automatically stop when the requirements are met

13.Built-in viscosity, moisture and temperature sensor modules, providing viscosity, moisture content saturation, ppm value and temperature reference value while accurately testing particle distribution (optional)

14.The particle size can be set arbitrarily, with nearly 10,000 built-in particle sizes, which is convenient for particle size analysis

15.A variety of sampling containers such as standard sampling bottles or sampling cups can be used to meet the testing requirements of different industries

16.Full-function 7-inch color touch screen operation, folding button design, support Chinese and English dual interface, easy and convenient operation

17.Manual, automatic and half-count calibration can be performed

18.Has RS232 interface, supports 485 communication, can be connected to computer or laboratory platform for data processing

19.It has massive data storage and printing functions, and supports U disk storage, and the data stored in this machine can be exported to U disk

20.Have more than 5 account settings, and set the operator authority separately

Technical Parameter