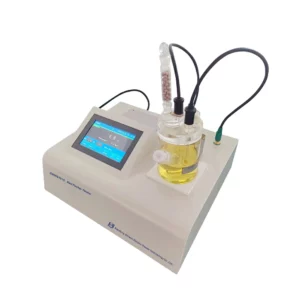

Oil Flash Point Tester

As leading oil flash point tester manufacturer in China, ZHIWEI Own CE, quality management system certificate GB and Patent certification for our Oil Flash Point Testers. Additionally, we have involved in this industry over 2 decades and cooperated with chemicals and water treatment companies, China power plants, etc. So there are some warm information about products oil flash point testers below, ZHIWEI expects customers to know no matter domestic or abroad.

Quality Oil Flash Point Tester Supplied By ZHIWEI

Evaluating the flash point of oils, fuels and other flammable liquids is crucial to ensure workplace and product safety. An automatic closed cup flash point tester streamlines this important quality control process.

Top 6 Features List Below About ZHIWEI Testers For Oil Flash Point Testing

Precise Temperature Measurement:

Look for testers utilizing platinum resistance thermometers providing temperature readings accurate to 1.5°C or better. This precision prevents retests from marginal passes or fails.

Meets International Standards:

Compliance with ASTM D92, ISO 2719 or other methods reassures test validity is on par with lab standards. Consistent results remain admissible for product certification or investigation of fires.

User-Friendly Operation:

Touchscreen interfaces simplify operation versus complex dials. Preset tests expedite common samples versus manual method selections. Built-in clocks record sample IDs and timestamps for documentation.

Dot Matrix Printing:

Hardcopy reports preserve cleveland open cup flash point tester parameters and flash/ignition point values as permanent records. Some models support optional computer connectivity for electronic recordkeeping.

Forced Air Cooling:

This cooling mechanism replicates standard test conditions more closely than water-cooling designs. Temperature remains stable throughout testing various petroleum products.

Robust Construction:

Heavy gauge steel chambers withstand frequent testing of aggressive chemicals or fuels. Digital controls withstand dusty or damp environments in factories, fuel terminals and R&D labs.